HERMES Q

Features

1 Operation panel

Self-explanatory symbols are on display. The device can thus be operated intuitively and settings be configured easily.

2 Ribbon holder

On the basis of three-part tightening axles, ribbons can be replaced easily and quickly.

3 Rugged metal chassis

It is made of cast aluminum. All the parts are assembled to it.

4 Applicator

It is assembled to hinge pins. It can be pivoted in case of maintenance or if materials have to be replaced.

5 Pressing plungers

One is fixed near the chassis wall. The second one is pushed to the label margin, as far as necessary to evoke a good print image.

6 Print head

Units of the same width are interchangeable. Replacement requires only few steps.

7 Print roller

It can be removed/inserted quickly in cases of cleaning or wear.

8 Peel-off plate

Pivoting improves labels be applied to packages.

9 Label unwinder

A swing arm and an integral brake enable labels be unwound at constant force.

10 Liner rewinder

Subsequent to all the labels been dispensed, the entire liner tape is rewound. On the basis of a three-part tightening axle, liner tapes can be inserted and removed easily.

11 Pulling system

A liner tape is clamped between a draw roller and a pinch roller. Labels are dispensed using feed synchronous to the print roller.

12 Label sensor

Imprint is precisely set on spot on a label and materials ending detected by a transmissive or a reflective sensor.

Accurate imprint

The smaller a label, the higher are the demands regarding the accuracy of an imprint. Print offset can be reduced by ±0,2 mm using adjustable slip correction.

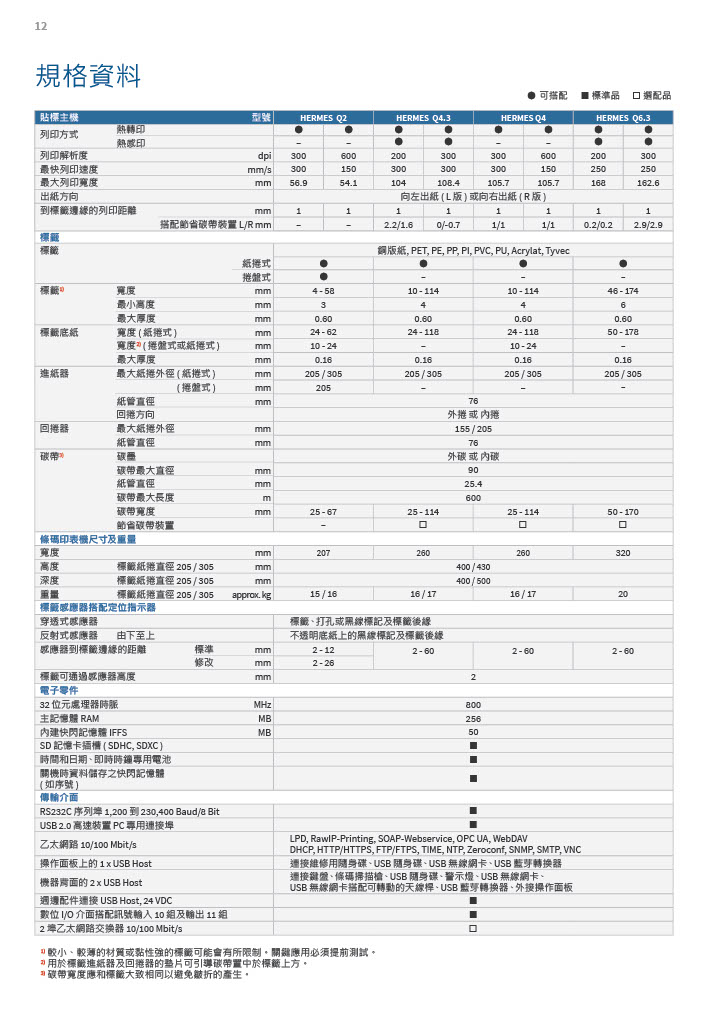

Specifications